| SHIFTY BUSINESS |

|

|

INSTALLATION OF JERRY?S

SHIFT IMPROVER KIT

IN A 1995 4R70W THUNDERBIRD

By Anthony Frusco

A-Train

NOTE: This

information is based on a pre-modified main control unit and is a supplement to

Jerry's thesis/novel. This report is to show you how to remove the main control

and accumulators for Jerry?s shift improver kit.

Last

Update: 1-9-02 Applications include any 94-?97 3.8L/4.6L T-Bird or Cougar.

The

parts/materials required to perform the installation.

Jack

(hydraulic, two preferred)

Jack stands

and/or ramps

Qaulity

Snap ring/retaining ring pliers (with assorted tips)

Metric sockets (deep and regular)

18mm, 10mm,

8mm, etc.

Flat-head

screwdrivers (medium size)

1/4",

3/8", and 1/2" ratchets and extensions

15 qt.

capacity catch pan

6-ft. of

3/8" ID hose or equivelant

5/16"

upper radiator fittings

Inch-pound

torque wrench

Needle-nose

pliers

Regular

pliers

Brake

cleaner (F6AZ-2C410-AB), 12 oz. can

Paper

towels and shop rags

Speedy dry

or Kitty litter

STEP #1:

Apply the emergency brake and open the hood, then disconnect the fan wiring

harness.NOTE: This is because the

electric fan may come on at any time, even while the engine is off. Place a

suitable 12-15 qt. container near the front of the car. You may wish to raise

the vehicle on jack stands or ramps at this time.

STEP #2:

Remove the upper radiator transmission line fitting from the radiator fitting.

Attach a 5/16" adapter to the radiator to allow connection of a 6 ft.

long, 3/8" ID hose (if necessary). DO NOT attach the hose to the metal

transmission line. Run the hose from the fitting to the large capacity pan on

the ground. Secure the hose to the fitting properly with an adjustable clamp.

If you

are installing a transmission cooler, follow the procedure below.

Remove the

upper radiator transmission line fitting from the radiator fitting. Remove the

radiator fitting that is threaded in the radiator. Install a new 5/16? inverted

flare to ?? male NPT fitting into the radiator. Then install a flared fitting

with a 3/8? hose barb into the inverted flare fitting. Use thread sealant

between the two fittings. Push a hose over the barbed end and secure it with a

hose clamp. Run the hose to the large container on the ground. Note: If you are

using empty gallon water containers. Generally, you will get one full gallon

and a ? gallon of ATF out this way.

STEP #3:

Start the engine and let the ATF pump into the pan. This process takes only a

few minutes and requires two people. You may slightly rev the engine to

activate the pump at a higher capacity, but do not exceed 1,200 rpm. Once the

ATF fluid starts spitting or the flow rate slows significantly, stop the engine

quickly. Failure to stop the engine could result in transmission damage as the

pump sucks up air. Re-install the transmission line to the radiator fitting and

discard the 3/8" ID hose. NOTE: Now is an excellent time to install an

auxiliary transmission cooler.

STEP #4:

Safely support the vehicle on jack stands and/or ramps, then move the large

capacity pan to under the torque converter. Remove the rubber access plug from

the bell housing shield using a flathead screwdriver.

You will

have to rotate the engine to align the torque converter drain plug with the

access hole in the bell housing shield. The easiest way to do this, is to place an 18mm socket and ?? drive (or breaker

bar) over the crankshaft pulley bolt. Then rotate the crankshaft CLOCKWISE

until you see the drain plug through the hole in the bell housing. Another way

to do this, is to disconnect the coil pack electrical

connectors. Then crank the engine, to align the drain plug (two people make

this task easier).

Remove the

torque converter drain plug and allow the ATF to drain. It will take about 30

minutes to completely drain the torque converter.

STEP #5:

Remove the transmission pan by loosening the 14, 10mm pan bolts. By draining the

transmission through the cooler lines, the pan will therefore have less than a

quart of ATF in it. Drop the pan carefully to avoid spilling any remaining ATF.

Remove the filter assembly and verify the filter seal was removed from the

bore. Drop the filter into the pan. Discard the plastic plunger that may be

floating in the pan. It was used to plug the dip stick hole during the factory

assembly. Allow the transmission to drip thoroughly before removing the main

controls (valve body).

STEP #6:

While the transmission and torque converter are draining together into the

large capacity catch pan, remove the electrical connectors to; the TCC (torque converter clutch) solenoid

- 7G136, shift

control solenoids - 7G484, EPC (VFS) solenoid - 7G383, and the TOT

sensor, the plastic tab on the main controls - 7H141.

STEP #7:

Transfer the magnet from the original '94-'95 4R70W transmission pan to the new

'96 deep sump pan (F6AZ-7A194-A). There is also a

'98 deep sump pan with a drain plug available (F8UZ-7A194-AA).

NOTE: This step does not apply to '96-'97 T-Birds and Cougars, since they

already have the deep sump transmission pan and corresponding filter assembly.

Be sure to clean the magnet thoroughly with the brake cleaner spray. NOTE: DO

NOT spray near the vehicle as the overspray will attack the paint. Be sure to

wear safety glasses when using the brake cleaner spray. Clean out the new

transmission pan as well to remove any debris that may have settled during

packaging or shipment. Place the magnet in the same spot as it was located in

the original pan. Place the pan to the side for the time being. NOTE: If you

are re-using the original pan, it must be thoroughly cleaned out as well.

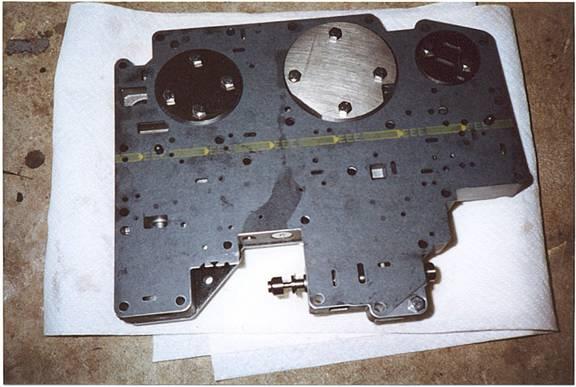

STEP #8: Remove the 25-8mm main control (valve body)

bolts. Start with the EPC/VFS solenoid bracket and remove that bolt (1), then

the bracket. Then remove the 12 bolts around the valve body plate or the

shorter length 8mm bolts. Finally, remove the 12 longer length 8mm bolts inside

the valve body plate. Note one of the bolts retains the Rooster Comb Spring

(with the roller attached to it). Make a drawing or write down a brief

description of the manual valve and the detent lever set-up.

The manual valve is the

valve shown here in this photo. The detent wheel?s pin attaches in the FIRST

section on the valve (the very thin part before the c-clip ring).

Carefully

lower the valve body into the original transmission pan or have somebody ready

to receive it. It will be heavier than you expect. Move it to the work bench.

Be careful, as the 2-3 accumulator retainer and spring may fall out and drop

into the fluid pan below. NOTE: To perform the main control modifications, your

working environment should be as sterile as possible and free of debris. Once

you get the main control down and on the bench, you may wish to remove the

shift solenoids from their bore. This is optional, but it does make the main

control easier to work on. To remove the shift solenoids, loosen the bolt

retaining them. Then wiggle the solenoids back and forth while carefully

pulling upward. The solenoids will pull out without much effort. Inspect the

snout of the solenoids for cracks. If there are any, replace the solenoid pack

with a new one. Use the p.n. that is on the pack. Do not re-use the solenoids

if the snouts are cracked.

I will not

go into detail on how to modify the main controls in this report, considering

they may vary from vehicle-to-vehicle per application. Consult with my ?Valve

Body How-To? report or Jerry's thesis/novel for exact instructions on

how to perform the changes to the main controls (shift improver kit). This also

applies to the Inject Tech?s pre-drilled separator plate. Perform the

modifications at this point.

STEP #9:

Modify the main controls or swap the pre-drilled separator plate. Refer to the ?how-to? report.

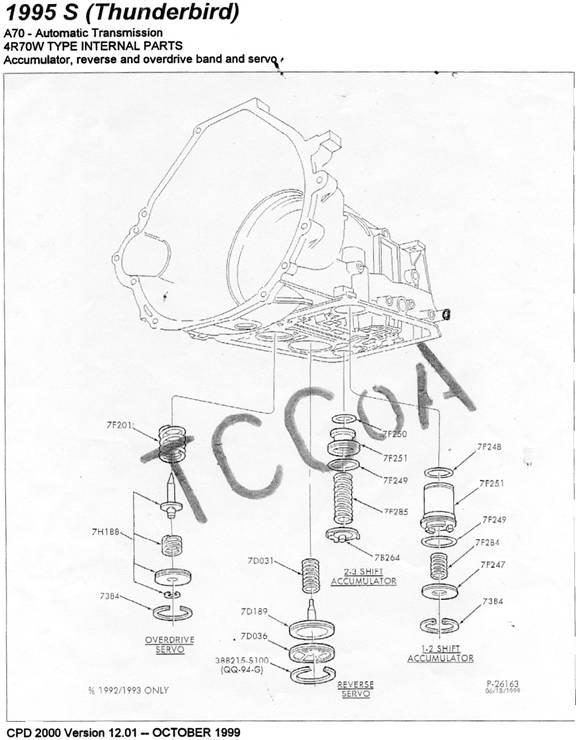

STEP #10: 2.7" OVERDRIVE SERVO (if applicable). To remove the OD Servo (see the CPD

Drawing for the bore location) the valve body must be removed before hand. When

you remove the main controls, you will find a hole in the case next the OD

servo bore. The hole goes through to the barrel of the transmission where you

will see the OD band. If you remove the OD Servo and do not anchor or hold the

OD band, it can move when you attempt to re-install the OD servo. If this

occurs, you will not have access to the Overdrive gear (4th).

BEFORE you

remove the OD servo, use the Rooster Comb Spring (the flat metal part with the

roller on the end of it), p.n. 7E332, to wedge against the OD band. Install it into the

hole next to the OD servo bore so that the roller is sticking out. Wedge it

against the back of the OD band and the transmission case, but do not damage

the Rooster Comb Spring. Remove the snap ring retaining the OD servo using

small screwdrivers or snap ring pliers. Next, remove the OD servo from the

bore. If

you should hear/feel the OD band fall, do not panic. You can push up on the

pocket once the OD servo is removed from the bore. You will quickly learn that

when you push up on the pocket, the OD band moves and the hole on the side will

no longer be visible. The tip of the OD servo must contact the

pocket

(dimple) in the band.

While still

holding the OD Band in place with the Rooster Comb Spring, install the new

2.7" OD servo (F75Z-7H188-AA) and the appropriate return spring

based on your horsepower level. NOTE: The 2.7" OD Servo does not have the

metal sleeve like the stock 2.5" OD servo. Simply place the NEW return

spring p.n. F87Z-7F201-AA over the servo

piston so it sits in the perch. Apply some fresh ATF to the rubber seal around

the edge of the new servo, then install the 2.7" OD servo into it's bore. Be sure to install it so it does not enter on an

angle.

In the bore you will notice two grooves. The snap ring (7384) must be installed in the second groove. To do

this, it may be necessary to use a hydraulic jack, with a large deep socket to

help hold the servo up into the bore while you install the retaining ring (see

Reverse Servo). Place the large diameter deep socket (i.e.

1-1/16")

on the tip of the jack mount and raise the jack height to reach the OD servo

bottom. Then slowly increase the height until the second groove in the bore is

visible. DO NOT over force the servo

up into the bore with the hydraulic jack, or damage to the transmission could

occur. Once the snap ring is installed, you can remove the Rooster Comb spring

from the hole.

ADDITIONAL

NOTES:

In Step

#13, the "shifter roller" is the Rooster Comb Spring, p.n. 7E332. Obviously, it needs to be re-installed on

the valve body. You can also use a screwdriver to perform this step.

You cannot

use spring p.n. F3LY-7F201-A

or the stock 2.5? OD servo spring with the 2.7" OD servo.

STEP #11: REVERSE SERVO (if applicable). To

remove the reverse servo (the largest bore), remove

the retaining ring with a small screwdriver. The servo will pop out fairly

easily. Be sure not to lose the return spring (7D031) that goes on the top of

the servo or the retaining clamp between the retaining ring and the servo

(7D036). Apply some fresh ATF with your finger to the rubber seal before

installing the servo. Install part number E0AZ-7D189-A

and it has only one groove (or ring) on the servo. Be sure to re-install the

retaining clamp and return spring as well. It may be necessary to use a 1-1/16"

socket and 2" extension as well as a hydraulic jack to hold the new

reverse servo up in its bore while you install the snap ring. DO NOT OVER-APPLY

PRESSURE TO THE SERVO with the hydraulic jack or damage to the transmission

could occur.

STEP #12: 1-2 ACCUMULATOR PISTON.

To remove the 1-2 accumulator piston, remove the snap ring using snap

ring/retaining ring pliers. WARNING: The 1-2 accumulator pistons spring and

snap ring may eject with extreme force when you release the snap ring. This

depends on the accumulator spring set-up your vehicle has.

Remove the snap ring with a good pair of snap ring

pliers.

The 1-2

accumulator piston should pop out of its bore fairly

easily. If not, push up on it with your fingers or an extension to re-act the

return spring. Use Scotch-Brite on the accumulator bore if it is slightly

scored. Spray brake cleaner to clean out the bore before you install the new

updated accumulator piston. Allow the brake cleaner to evaporate before

installing the new piston. Apply some fresh ATF with your finger to the rubber

seals on the accumulator piston before installing it.

Photo from Jerry?s

thesis.

Install the

new rubber bonded accumulator piston (F7AZ-7F251-AA)

and use the blue return spring on the top (F75Z-7F284-AA).

Do not install the original spring on the bottom of the piston. Leaving the

spring out will firm up the 1-2 upshift. Re-install

the accumulator retaining cover (7F247)

followed by the snap/retaining ring (7384). The

orientation of the accumulator cover can be confusing if your

not paying attention when it?s removed. Always look for the marks in the spring

perch inside the cover, to tell you which end is up.

Obviously, the marks mean the spring was rubbing and that end is up. There is

also a part number stamped into the cover, the p.n. goes down. Use the

snap/retaining ring pliers to re-install the snap ring.

STEP #13: 2-3 ACCUMULATOR PISTON.

To remove the 2-3 accumulator piston, simply remove

the main controls (valve body). The retainer and return spring will fall out

freely (the original piston is made of all-aluminum). Use a pair of needle nose

pliers to pull the 2-3 accumulator piston out from it?s

bore. Clean out the bore with brake cleaner and allow some time for it to

evaporate. Apply fresh ATF with your finger, to the seals on the 2-3

accumulator piston. Then install the new rubber bonded

2-3 accumulator piston (F7AZ-7H292-AB).

Do not re-install the stock return spring, or any return spring for that

matter. You will have to bend the tabs out on the retaining clamp (7B264) SLIGHTLY with a pair of pliers in order

to keep the 2-3 accumulator in it's bore.

STEP #14: EPC(VFS) Solenoid (if applicable). To remove the old EPC solenoid, you must remove the retaining nut from the shifter

linkage using a 13/16" wrench. There is also a small pin that must be

removed using needle-nose pliers. Do not lose the small pin as it will be

re-installed later.

Carefully

remove the EPC solenoid and replace

it with the '96 version (F6AZ-7G383-AA).

Re-install it in reverse order. You must use a new style EPC bracket (F6AZ-7H111-A)

with a '96 and newer style main control unit. NOTE: The '96-'97 T-Birds and

Cougars already have the new style bracket.

Please note

that a different higher pressure solenoid exists as well (XL3Z-7G383-AA).

However for pre-1998 models (through 1997), you must cut the

pigtail from the wiring harness and solder the wires (or crimp connect as shown

in Jerry's thesis) to the new style EPC solenoid's connector. This was

done because of the wireless connectors (circuit board) used in the 1998 model

4R70W transmissions. Note: If you are installing Jerry?s Shift Improver kit,

you do not have to change the EPC solenoid. Replacing the EPC solenoid is

optional and for high HP applications. You do not need to use the higher

pressure solenoid, its optional. DO NOT under any

circumstance adjust the screw in the rear of the EPC solenoid, or transmission

damage could occur.

STEP #15:

Re-install the main controls (valve body) at this time. Be sure that the 1-2 Accumulator, 2-3 Accumulator, Reverse Servo, and EPC

solenoid are up in their proper locations (especially the 2-3 accumulator)

before proceeding. There is also a little black cone-shaped filter that goes

into the transmission case near the rear of the transmission (towards the

driveshaft). Be sure that it hasn't fallen out as well. DO NOT LEAVE IT OUT.

Verify that you have properly performed the main controls (valve body)

modifications before continuing. NOTE:

If you are installing a '96 and newer style main control (suggested is '99) in

an older style case ('94-'95 4R70W), you must install two pilot sleeves (F6AZ-7K720-A), they are sold in a package of

two. Place them over the two black tips on the top of the main controls and

install the assembly into the transmission case.

You must

align the manual valve with the detent wheel?s pin. See the previous photo. The

pin gets inserted into the FIRST section on the manual valve (the thin part

before the c-clip ring). The Rooster Comb spring?s roller should be in the

fourth (4th) detent when the transmission is in Park. You must do

this correctly or you will not have access to all gear selections.

You can see the

shift solenoids in this photo. This photo may vary from your main control, its just for reference.

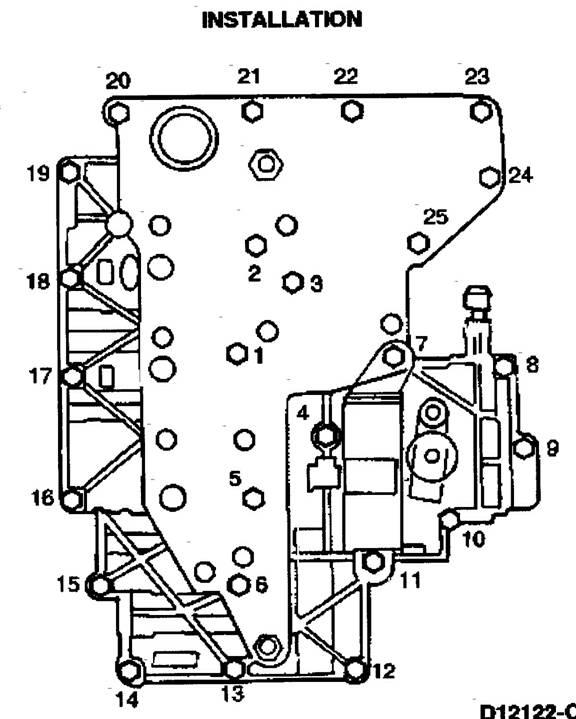

STEP #16:

Spray the inside of the transmission case with brake cleaner spray to remove

the ATF fluid from your work area. Install the valve body in the reverse order

as it was removed. Carefully thread two of the longer 8mm bolts into the

opposite ends of the main controls, to hold it in place. Re-install the

remaining 23 bolts that retain the valve body. Torque the bolts to 90 in.-lbs.

Hook up the electrical connections to the various sensors. Here is the check

list; TCC (Torque converter clutch) solenoid,

Shift solenoids, EPC solenoid, and black plastic tab (7H141). Be careful not to incorrectly hook up the

solenoids to the wiring harness or transmission damage could occur. See the CPD

drawing below for details. The following

shows you the torque sequence for the main control bolts.

IMPORTANT:

Re-install and tighten the bolt that secures the shifter linkage if you have

removed the EPC solenoid. Then install the pin and roller. Be sure to verify

the shifter still works and you can remove the key in Park. Turn the key to the

on position (DO NOT start the engine) and move the shifter through the gears,

then remove the key. If you cannot remove they key in Park, you must re-adjust

the linkage. This step is not difficult, but it is important.

STEP #17:

Install the '96 filter (F6AZ-7A098-A)

assembly into it's bore in the main controls. Regardless of which year transmission you have ('94-'97) you have

to install the '96 filter. Apply fresh ATF with your finger to the

filter seal before installing it.

STEP # 18:

Install the '96 (or '98) deep sump transmission pan

(F6AZ-7A194-A). NOTE: The '96-'97 T-Birds and

Cougars are equipped with the deep sump pan from the factory. Re-use the

original transmission pan gasket ('94-'97), provided it is not ripped or

damaged. It is fairly durable and the '96 pan actually states, "This pan

is equipped with a re-usable gasket". Bolt up the pan using the original

14, 10mm bolts. Tighten the pan bolts up to 120 in.-lbs. of torque. IMPORTANT:

If you have a cork style gasket instead of the factory gasket, it is highly

recommended you upgrade to the p.n. F2VY-7A191-A. This is also the p.n. for the

gasket in case you rip or damage your re-usable one.

STEP # 19:

Re-install the torque converter drain plug and torque it to 22 lbs-ft. or 30

N-m (this is hand tight). Then pop the rubber seal in the bell housing shield.

NOTE: Re-install the fan wiring harness at this time.

STEP #20:

Fill the transmission through the dip stick tube. Add 6 qts. of

MERCON-V ATF (XT-5-QM)

at first. Hold the brake firmly and start the engine. Move the shifter level

through the gears, stopping at each indent or position. Do not panic if you do not feel the

transmission engage into gear. Stop the engine and add 6 more quarts of MERCON-V ATF to the dip stick tube.

Stop again at 10 qts. and repeat the process listed

above. The 4R70W holds 12-13 quarts of ATF fluid, do not over-fill the

transmission. NOTE: If you have an auxiliary transmission cooler, you will

require 13-14 quarts of ATF.

STEP #21:

Inspect the pan and transmission for leaks. Then carefully lower the vehicle to

the ground. Start the engine and allow the transmission to warm up to normal

operating temperature, listen for strange noises or smells. If you see smoke,

do not panic, it is just the ATF burning off of the exhaust parts. Once the

engine has warmed, rev the engine slightly (to activate the pump). Then move

the shifter lever through the gears. Hold each gear for at least one second

before changing to a new indent or position. You should feel the transmission

engage each gear followed by a decrease in engine rpm.

STEP #22:

Road test the vehicle. Observe the shifting, firmness of the shifts and rpm of

the shift points. Also check reverse and forward gear characteristics.

Accelerate to 45-50 mph and press the Overdrive "ON/OFF" button

located on the shifter handle. Verify that the transmission has engaged 4th

(OD) gear and that the vehicle accelerates properly. Verify you can manually

shift the transmission in the 1-2 and 2-3 positions.

STEP #23:

Re-check the clamps on the transmission cooler lines and auxiliary cooler.

Check to make sure you have no leaks, especially under the pan or TC. Verify

that your fluid level is correct in both "Cold" and "Warm"

conditions. Enjoy your new upgrades. Be sure to re-check the clamps and fluid

level on a regular basis after you install the modifications listed above.

Estimated installation time 6-7 hours.

Please

dispose of the ATF and used parts according to your local and state laws. Clean

up any spilled ATF fluid using proper methods. Animals are attracted to the

ATF, and it is very harmful to them. Wear nitrile gloves if your skin is

sensitive to the ATF's properties. Special thanks to Adam H. for turning the

wrenches and Jerry for the modified main controls and technical support.

NOTE: The TCCOA, nor the author assumes responsibility for damaged

and/or broken materials during the installation of the aforementioned parts.

This document is solely designed as a supplement to a Ford Motor Company shop

manual.

| Sponsor Links |

|

|

|